W-00 (W 000) Inch Lock Washer

CS locking washers are made of SPCC / SPHC metal materials. Surface treatment: Zinc plated 5um, Cr3+. The purpose in using them is to keep nuts and bolts away from vibrating or friction loose. There are many different shapes and sizes, but they all try to achieve the same goal. When properly applied, lock washer provides an easy, basic way to keep threaded fasteners steady over a long period of time.

Professional and well-experienced manufacturer of Inch lock washer with "CS" Brand, finest quality Inch lock washer manufacturer and a famous Inch lock washer exporter in Taiwan, supplying Inch lock washer to all over the world. Inch lock washer agent, Inch lock washer distributor are wanted.

Model

W-00, W-01, W-02, W-03, W-04, W-05, W-06, W-07, W-08, W-09, W-10, W-11, W-12, W-13, W-14, W-15, W-16, W-17, W-18, W19, W-20, W-21, W-22, W-24, W-26, W-28, W-30, W-32, W-34, W-36, W-38, W-40, W-44

W-022, W-024, W-026, W-028, W-030, W-032, W-034, W-036, W-038, W-040, W-044

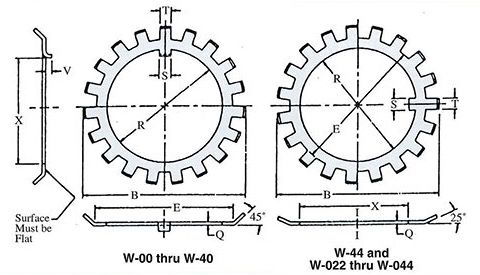

Drawing

Lock Washer Dimensions (Inches) - W-00 / W000

W-00| Lock Washer NO. | Bore | Face Diameter | Diameter Over Tangs | Key Width | Inside Dimension | No of Tangs | Project | Tang Width | Tang Thickness |

|---|---|---|---|---|---|---|---|---|---|

| R | |||||||||

| E | B | S | X | V | T | Q | |||

| nom | min | max | max | min | min | max | min | ||

| W-00 | 0.406 | 0.625 | 0.875 | 0.120 | 0.334 | 9 | 0.062 | 0.120 | 0.032 |

| W-01 | 0.484 | 0.719 | 1.016 | 0.120 | 0.412 | 9 | 0.062 | 0.120 | 0.032 |

| W-02 | 0.601 | 0.813 | 1.156 | 0.120 | 0.529 | 11 | 0.062 | 0.120 | 0.032 |

| W-03 | 0.679 | 0.938 | 1.328 | 0.120 | 0.607 | 11 | 0.062 | 0.120 | 0.032 |

| W-04 | 0.801 | 1.125 | 1.531 | 0.176 | 0.729 | 11 | 0.062 | 0.166 | 0.032 |

| W-05 | 0.989 | 1.281 | 1.719 | 0.176 | 0.909 | 13 | 0.094 | 0.166 | 0.040 |

| W-06 | 1.193 | 1.500 | 1.922 | 0.176 | 1.093 | 13 | 0.094 | 0.166 | 0.040 |

| W-07 | 1.396 | 1.813 | 2.250 | 0.176 | 1.296 | 15 | 0.094 | 0.166 | 0.040 |

| W-08 | 1.583 | 2.000 | 2.469 | 0.290 | 1.475 | 15 | 0.094 | 0.234 | 0.048 |

| W-09 | 1.792 | 2.281 | 2.734 | 0.290 | 1.684 | 17 | 0.125 | 0.234 | 0.048 |

| W-10 | 1.992 | 2.438 | 2.922 | 0.290 | 1.884 | 17 | 0.125 | 0.234 | 0.048 |

| W-11 | 2.182 | 2.656 | 3.109 | 0.290 | 2.069 | 17 | 0.125 | 0.234 | 0.053 |

| W-12 | 2.400 | 2.844 | 3.344 | 0.290 | 2.267 | 17 | 0.125 | 0.234 | 0.053 |

| W-13 | 2.588 | 3.063 | 3.578 | 0.290 | 2.455 | 19 | 0.125 | 0.234 | 0.053 |

| W-14 | 2.791 | 3.313 | 3.828 | 0.290 | 2.658 | 19 | 0.188 | 0.234 | 0.053 |

| W-15 | 2.973 | 3.563 | 4.109 | 0.290 | 2.831 | 19 | 0.188 | 0.328 | 0.062 |

| W-16 | 3.177 | 3.844 | 4.375 | 0.353 | 3.035 | 19 | 0.188 | 0.328 | 0.062 |

| W-17 | 3.395 | 4.031 | 4.625 | 0.353 | 3.253 | 19 | 0.188 | 0.328 | 0.062 |

| W-18 | 3.582 | 4.281 | 4.938 | 0.353 | 3.418 | 19 | 0.188 | 0.328 | 0.084 |

| W-19 | 3.800 | 4.563 | 5.219 | 0.353 | 3.636 | 19 | 0.188 | 0.328 | 0.084 |

| W-20 | 3.988 | 4.813 | 5.500 | 0.353 | 3.809 | 19 | 0.250 | 0.328 | 0.084 |

| W-21 | 4.192 | 5.000 | 5.703 | 0.353 | 4.013 | 19 | 0.250 | 0.390 | 0.084 |

| W-22 | 4.395 | 5.281 | 6.063 | 0.353 | 4.185 | 19 | 0.250 | 0.390 | 0.115 |

| W-24 | 4.801 | 5.688 | 6.469 | 0.353 | 4.591 | 19 | 0.250 | 0.390 | 0.115 |

| W-26 | 5.191 | 6.188 | 7.031 | 0.435 | 4.961 | 19 | 0.250 | 0.520 | 0.115 |

| W-28 | 5.582 | 6.531 | 7.438 | 0.590 | 5.352 | 19 | 0.250 | 0.520 | 0.115 |

| W-30 | 5.983 | 7.063 | 8.063 | 0.590 | 5.722 | 19 | 0.313 | 0.520 | 0.146 |

| W-32 | 6.389 | 7.438 | 8.438 | 0.590 | 6.128 | 19 | 0.313 | 0.520 | 0.146 |

| W-34 | 6.764 | 8.031 | 9.063 | 0.715 | 6.503 | 19 | 0.313 | 0.520 | 0.146 |

| W-36 | 7.171 | 8.375 | 9.438 | 0.715 | 6.910 | 19 | 0.313 | 0.645 | 0.146 |

| W-38 | 7.577 | 8.781 | 9.875 | 0.715 | 7.316 | 19 | 0.313 | 0.645 | 0.146 |

| W-40 | 7.982 | 9.156 | 10.313 | 0.840 | 7.721 | 19 | 0.313 | 0.645 | 0.146 |

| W-44 | 8.701 | 9.875 | 11.438 | 0.940 | 8.327 | 19 | 0.878 | 0.146 |

| Lock Washer NO. | Bore | Face Diameter | Diameter Over Tangs | Key Width | Inside Dimension | No of Tangs | Tang Width | Tang Thickness |

|---|---|---|---|---|---|---|---|---|

| R | ||||||||

| E | B | S | X | T | Q | |||

| nom | min | max | max | min | max | min | ||

| W-022 | 4.395 | 4.921 | 5.688 | 0.350 | 4.185 | 19 | 0.390 | 0.115 |

| W-024 | 4.801 | 5.333 | 6.188 | 0.350 | 4.591 | 19 | 0.390 | 0.115 |

| W-026 | 5.191 | 5.723 | 6.625 | 0.469 | 4.961 | 19 | 0.390 | 0.115 |

| W-028 | 5.582 | 6.129 | 7.094 | 0.594 | 5.352 | 19 | 0.390 | 0.115 |

| W-030 | 5.983 | 6.708 | 7.719 | 0.594 | 5.722 | 19 | 0.520 | 0.115 |

| W-032 | 6.389 | 7.114 | 8.156 | 0.594 | 6.128 | 19 | 0.520 | 0.115 |

| W-034 | 6.764 | 7.508 | 8.594 | 0.719 | 6.503 | 19 | 0.520 | 0.115 |

| W-036 | 7.171 | 7.899 | 9.000 | 0.719 | 6.910 | 19 | 0.520 | 0.115 |

| W-038 | 7.577 | 8.290 | 9.438 | 0.719 | 7.316 | 19 | 0.520 | 0.115 |

| W-040 | 7.982 | 8.774 | 9.969 | 0.844 | 7.721 | 19 | 0.645 | 0.115 |

| W-044 | 8.701 | 9.570 | 10.406 | 0.945 | 8.327 | 19 | 0.770 | 0.115 |

- Download

Spec. of W-00

Spec. of W-00, W-01, W-02, W-03, W-04, W-05, W-06, W-07, W-08, W-09, W-10, W-11, W-12, W-13, W-14, W-15, W-16, W-17, W-18, W19, W-20, W-21, W-22, W-24,...

Download

W-00/W-000 Lock Washer: Durable, DIN-Compliant Bearing Safety

The W-00/W-000 inch lock washer is engineered for secure, vibration-resistant fastening of bearings and shaft assemblies. Manufactured to strict DIN standards, this washer prevents loosening and ensures operational safety, even in high-vibration environments. Its precise fit and robust design make it an essential component for machinery maintenance, automotive repair, and heavy equipment assembly.

Available in multiple sizes and ready for immediate shipping, our lock washers are trusted by OEMs and maintenance professionals worldwide. Download the technical datasheet or request a quote today. For selection support or application advice, contact our engineering team for expert assistance.